A prototype is an early version or model of a product or system that is made to check and assess its design, functionality and features. Prototyping is an important part of the product development process, as it allows designers and engineers to identify and address any issues or flaws before the final product is produced.

Prototypes can be made using a variety of materials and methods, including 3D printing, CNC machining, and injection moulding.

At the moment, China is a hub for exporting and manufacturing various products, including rapid prototypes. Rapid prototypes made in China are becoming increasingly popular due to the cost-effectiveness and the quick turnaround time.

In this article, we will explore the process of manufacturing rapid prototypes made in China.

Design phase

The manufacturing of quick prototypes in China involves a few key steps, starting with the design phase. The design is created using Computer-Aided Design (CAD) software, which is widely available and accessible.

Once the design is complete, it is sent to the rapid prototype factory, which uses Computer-Aided Manufacturing (CAM) software to convert the design into a format that can be used by the machines.

Selection of the appropriate materials

The next step in the process is the selection of the appropriate materials. The materials used in rapid prototyping can vary depending on the specific application and requirements of the product.

Some of the commonly used materials for rapid prototypes made in China include the following:

- Plastic

- Metal

- Composite materials.

Manufacturing process

Once the design and materials have been selected, the manufacturing process can begin. There are several methods used in rapid prototyping, including the following:

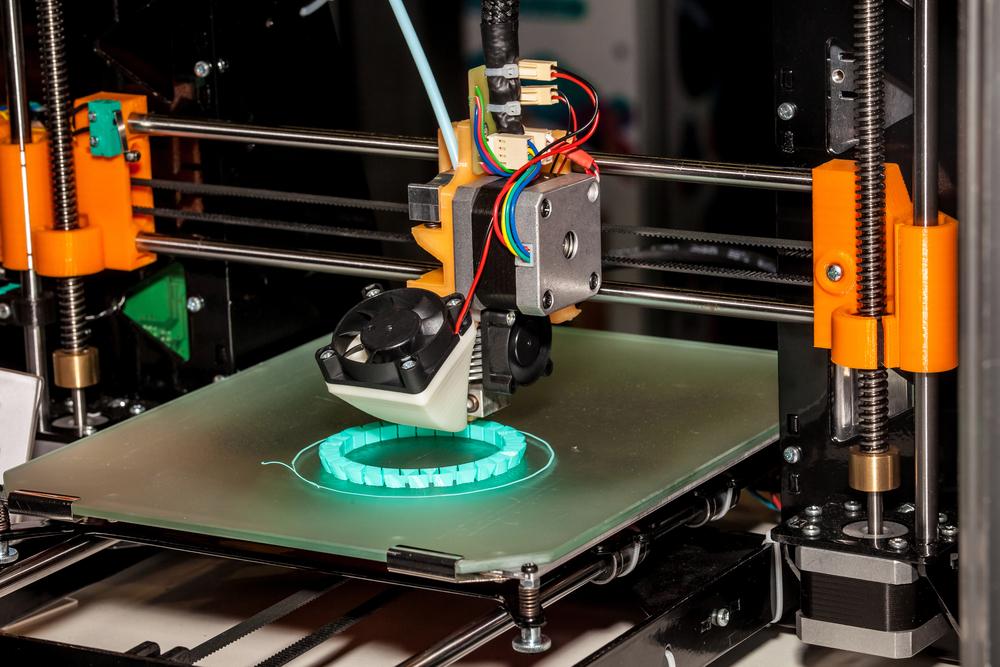

- 3D printing

- CNC machining

- Injection moulding.

Each method has its own advantages and disadvantages, and the choice of method will depend on the specific requirements of the product.

- 3D printing: In 3D printing, a computer-controlled machine is used to create a physical model of the design by building up successive layers of material.

This method is ideal for creating complex geometries and intricate designs quickly and accurately. 3D printing is widely used in the manufacturing of rapid prototypes in China due to its cost-effectiveness and quick turnaround time.

- CNC machining: CNC machining involves the use of computer-controlled machines to cut and shape the material into the desired shape.

This method is ideal for creating parts with high precision and accuracy, and it can be used with a wide variety of materials. CNC machining is commonly used in the manufacturing of rapid prototypes, which is made in China for applications where high precision is required.

- Injection moulding: Injection moulding involves the use of a mould to create a physical model of the design. This method is ideal for creating large quantities of parts quickly and efficiently.

Injection moulding is commonly used in the manufacturing of rapid prototypes when it is made in China for applications where high-volume production is required.

Once the rapid prototype has been manufactured, it is inspected and tested to ensure that it meets the required specifications. Any necessary adjustments or modifications are made at this stage, and the final product is produced.

Conclusion

In conclusion, the manufacturing of rapid prototypes made in China involves several key steps, including design, material selection, and manufacturing using various methods such as:

- 3D printing

- CNC machining

- Injection moulding.

China has become a popular destination for the manufacturing of rapid prototypes due to its cost-effectiveness, quick turnaround time, and access to a wide variety of materials and manufacturing methods.

With its high-quality products and efficient manufacturing processes, China is poised to continue to lead the way in the manufacturing of rapid prototypes.

3 comments

Great explanation of industrial processes and efficiency. Manufacturers seeking precision plastic parts can benefit by visiting plasticpartmanufacturing.com for advanced manufacturing capabilities.

Great content, keep sharing

Informative and useful post